What material will you choose for your caster wheels? PVC wheels or PU wheels?

What material will you choose for your caster wheels? PVC wheels or PU wheels?

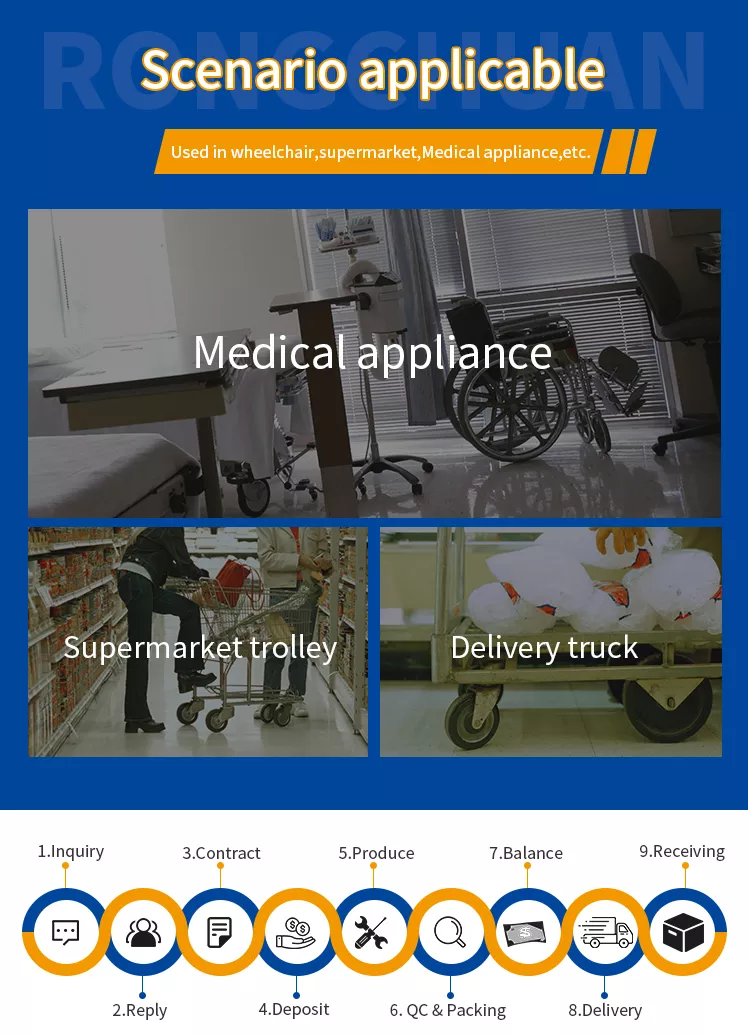

PU castersare durable, but the price is usually higher. Some people have low demand and are discouraged by the price of PU wheels. In response to market demand, PVC wheels came into being. Very close appearance and performance, relatively low price, very suitable for most low-end markets. So now, many people ask for PU Polyurethane Forklift Caster as soon as they speak, and then offer a very low price. Only PVC materials can meet this price. In fact, many people can't distinguish between PU and PVC casters. And some people directly sell PVC casters as PU casters.

There is basically no difference in appearance between PVC casters and PU casters. So how to distinguish them? What we are accustomed to is to smell, usually Medium Duty Plastic Core Red PVC wheel will smell a bit, PU wheels generally smell nothing. In the case of a long display time, it is easy to distinguish with the your eyes. If the caster made of PU material is not used for a long time, the surface will oxidize to form a layer of mist, only after wiped off you can see the original appearance; while the caster made of PVC keeps the original appearance, except for a little ash, basically no difference .

If you or your customers have high requirements, you can choose PU casters. If you or your customers pay attention to cost performance, then it is recommended that you choose PVC casters. After all, casters are originally consumables. If they are used frequently, both PVC and PU wheels will be worn out, and they need to be replaced to a certain extent.

After reading the above description, have you thought about which material to choose casters? Are PU casters or PVC casters?

We YLcaster is a powerful caster wheel manufacturer specializing in the design, production and sales of various caster wheels. We can provide you with either PVC casters or PU casters. In addition, it also supports various customization of casters. Friends who are interested and in need are welcome to consult and understand.